Engineering ceramics are those which have been specially produced to create ceramic components to provide solutions for engineering conditions with specialist requirements.

Engineering ceramics uses.

Such joints are usually associated with the demand for high or ultrahigh vacuum tightness and acceptable mechanical strength for use in the field.

Ceramics can be organised into types or categories in terms of composition oxide carbide and so on.

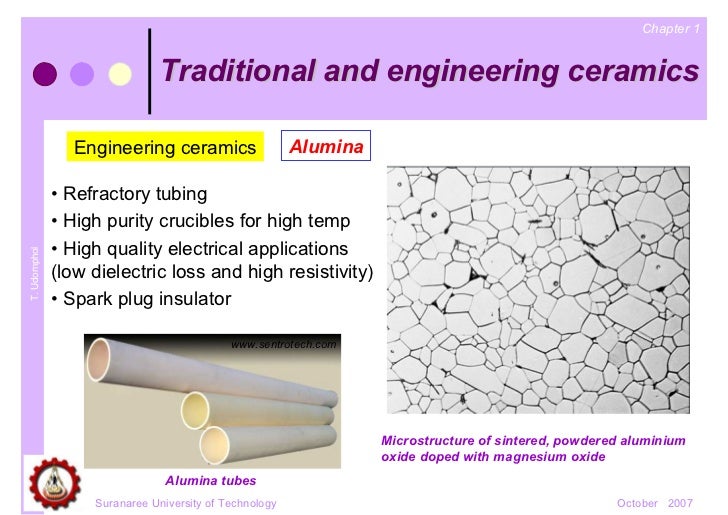

Alumina aluminium oxide al 2 o 3 is by far the most commonly used engineering ceramic and is generally specified as the ceramic of.

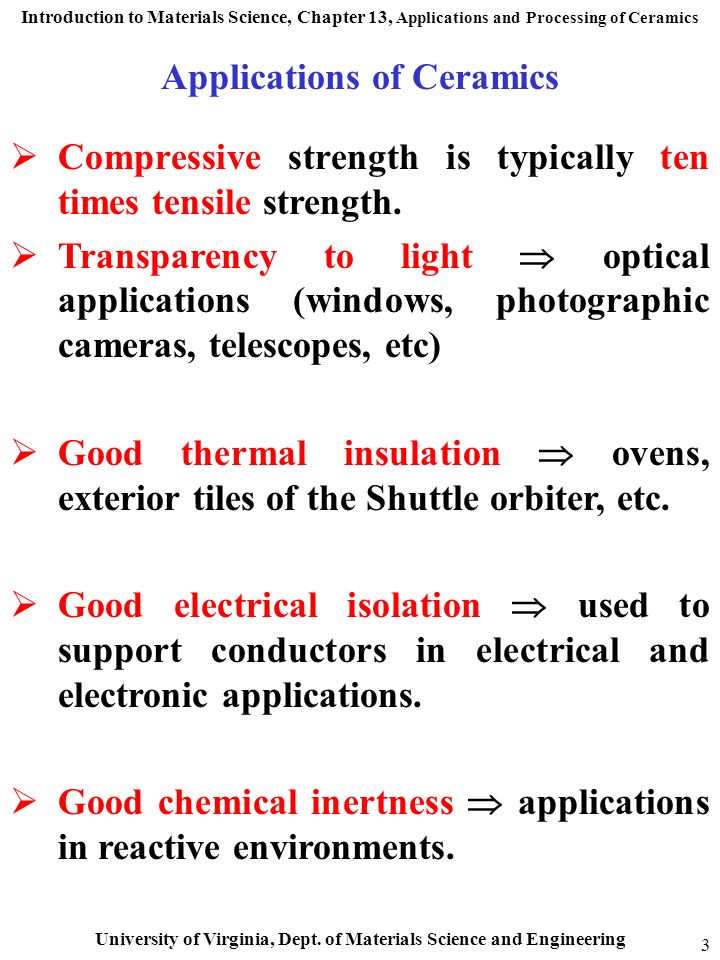

Given below are some other important uses of ceramics.

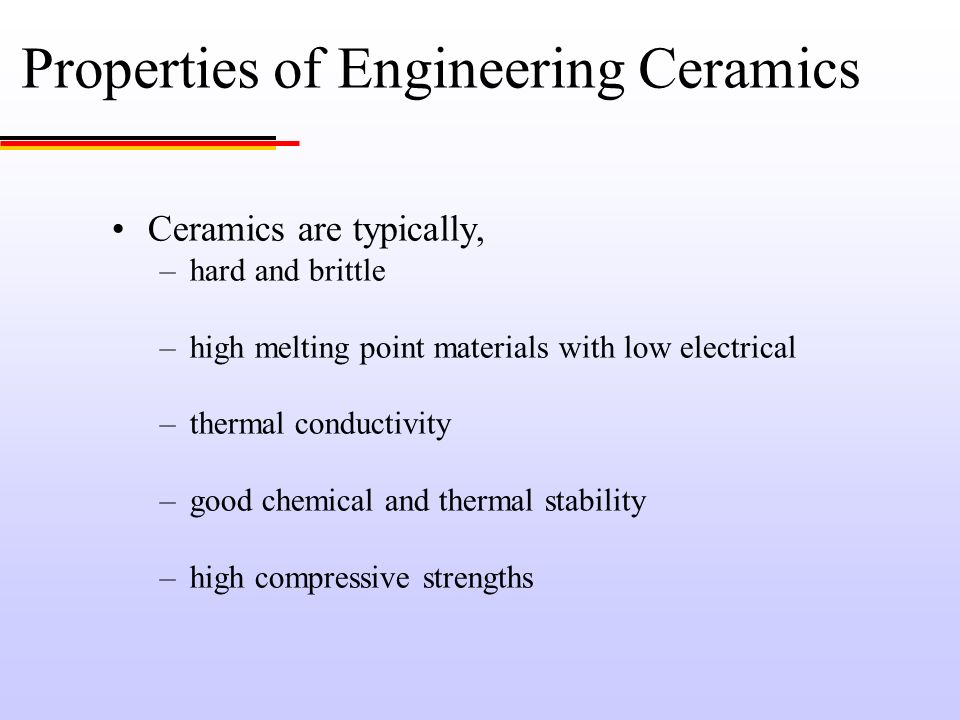

Ceramic materials can be identified by their general properties like high hardness brittleness chemical stability and low thermal conductivity.

Types of engineering ceramics.

The bauxite is crushed and purified and then heated to 1150 c to decompose it to alumina.

Ceramic may be used as a noun in the singular to refer to a ceramic material or the product of ceramic manufacture or as an adjective.

In the 20th century new ceramic materials were developed for use in advanced ceramic engineering such as in semiconductors.

Advanced ceramics and traditional ceramics are the main categories of ceramic materials.

Ceramics now include domestic industrial and building products as well as a wide range of ceramic art.

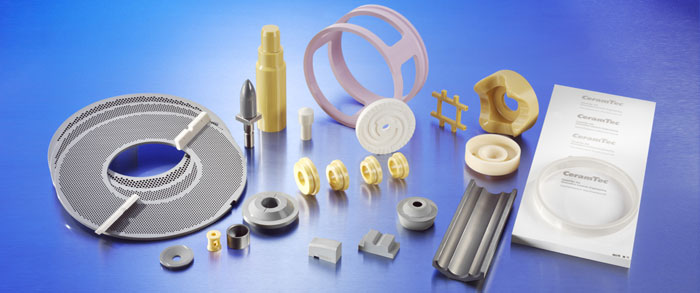

These material properties are utilized to produce number of commercial and domestic products such as pottery bricks advanced functional items etc.

Alumina aluminium oxide al 2 o 3.

Ceramics is the making of things out of ceramic materials.

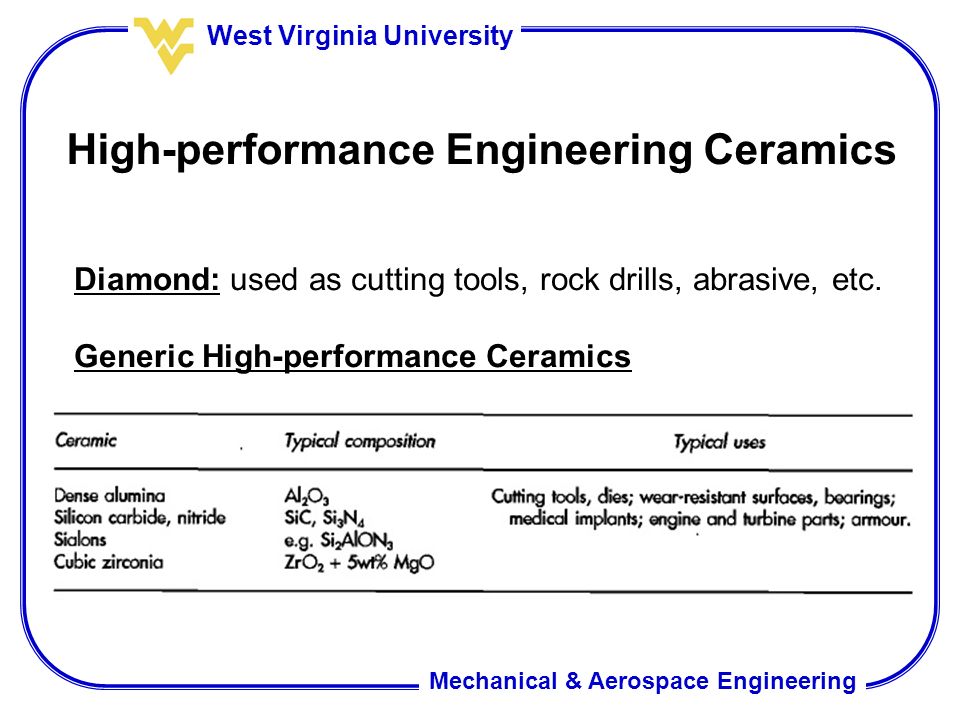

Engineering ceramics are based primarily on pure oxides carbides or nitrides.

The characteristics of some of the more common are given below.

The thermal stability wear resistance and resistance to corrosion of ceramic components make the application of ceramic the ideal choice for many industrial uses.

If aerospace is an extraordinary use for extraordinary ceramics construction is one of the best known uses for ordinary everyday ceramics.

As a result they are used to make pottery bricks tiles cements and glass.

Bio ceramics are used as dental implants and synthetic bones.

Ceramic products are hard porous and brittle.

Of these the most important compounds are alumina al2o3 silicon carbide sic silicon nitride si3n4 and zirconia zro2 alumina is made from a hydrated aluminium oxide known as bauxite al oh 3.

Ceramics are also used at many places in gas turbine engines.

Engineering ceramics such as silicon nitride silicon carbide and a large number of oxides are used in industries ranging from aerospace to automotive and biomedical to electronics.

The use of ceramic components in electrotechnical assemblies often demands material to material joints with one or more metallic components that can comprise different materials.

.jpg)

.jpg)