A temporary shape change that is self reversing after the force is removed so that the object returns to its original shape is called elastic deformation.

Elestic deformation of ceramics.

This temporary deformation of metals is.

Dokko and joseph a.

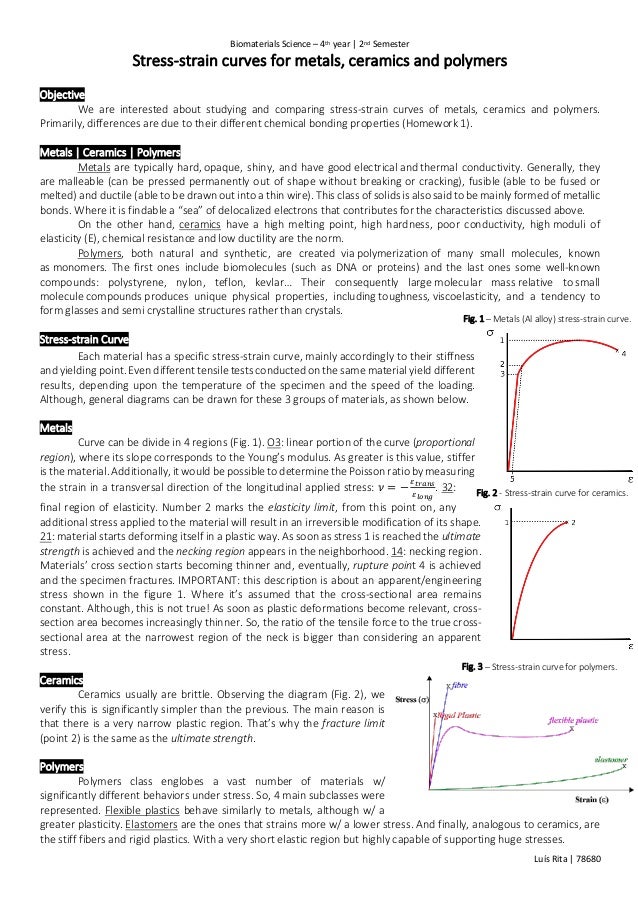

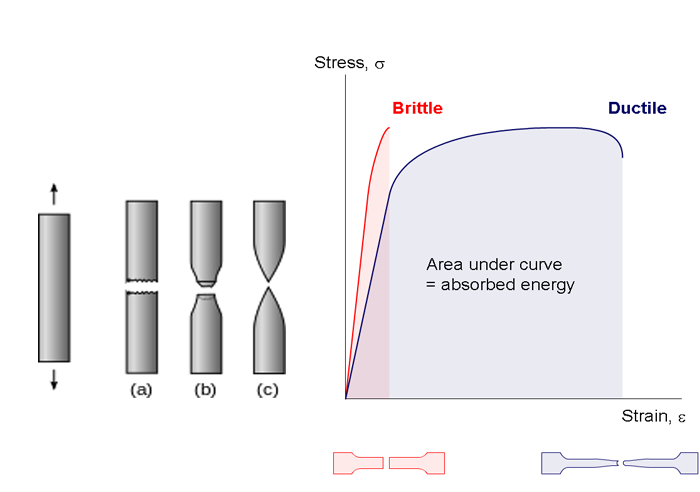

It is difficult to measure the yield strength of ceramics as they tend to fracture before they enter the plastic deformation region i e they are brittle.

94720 u s a summary the.

If we apply the load the material will deform up to the material can withstand the load.

Understanding elastic deformation is very important in ceramics to eliminate instantaneous brittle fracture at some applied stress levels.

Stresses have to be exercised with understanding of the limits of the specific ceramics and the level that it can endure before.

Materials science and engineering 25 1976 77 86 77 elsevier sequoia s a lausanne printed in the netherlands plastic deformation of ceramic materials philip c.

Understanding elastic deformation is very important in ceramics to eliminate instantaneous brittle fracture at some applied stress levels.

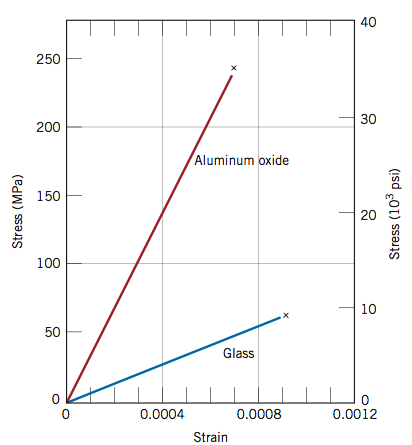

Examples of two brittle materials that fracture before entering the plastic deformation region are aluminum oxide and glass as shown in the figure below.

Its behavior begins in the linear elastic deformation region.

For polymer materials this peak stress is identified as the yield stress.

When the applied loads are removed metals return to their original shape.

The fracture stress is usually the same or very close to the elastic limit.

Particle size determines the physical properties.

Ceramics are generally brittle or ductile in nature.

When metals are placed under small loads or stresses they deform.

Above that the material breaks without neck formation this is elastic deformation.

After the external force is removed the material can return to the original shape of deformation.

Pask materials and molecular research division lawrence berkeley laboratory and department of materials science and engineering university of california berkeley calif.

Elastic deformation of metals and ceramics is commonly seen at low strains.

So what are the characteristics of elastic deformation of zirconia ceramics.

Porous ceramics are a class of materials used in several applications of industrial and engineering branch.

1 metal materials generally undergo two stages of.

Deformation can be elastic or plastic.

As the curve transitions from the elastic to plastic deformation typically there is a peak stress.

Corrosionpedia explains elastic deformation.

A highly elastic polymer may stretch over 10 times the original length before breaking.

Their elastic behavior is generally linear.

Likewise here stress and strain determine the strength of the material.

Elastic deformation refers to a certain amount of deformation of the material under the action of external force.